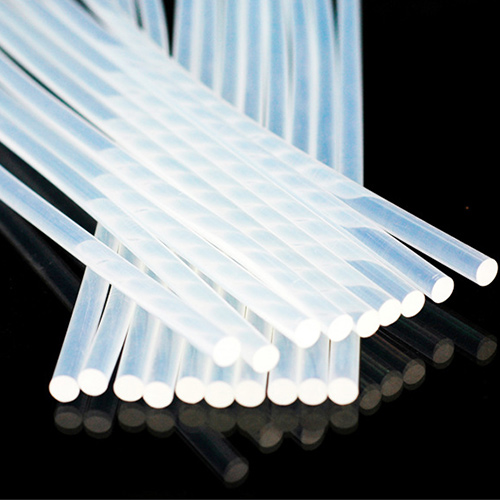

If you're in the market for a high-quality, versatile water-white thermoplastic resin for hot melt adhesives, look no further than the C5 Hydrogenated Hydrocarbon Resin-SHA158 Series. This product is produced by C5 hydrocracking and is known for its excellent performance and wide range of applications.

One of the main features of C5 hydrogenated petroleum resin-SHA158 series is its excellent thermal stability. This makes it ideal for hot melt adhesives, as the adhesive needs to maintain its strength and integrity even at high temperatures. Whether you are working in packaging, woodworking or nonwoven applications, this resin ensures your adhesives remain effective in challenging environments.

In addition to thermal stability, the C5 Hydrogenated Petroleum Resin-SHA158 Series offers low odor, making it a more pleasant choice for manufacturers and end-users. This is especially important for products such as diapers, feminine hygiene products and food packaging, where odor can be a significant issue.

In addition, the resin has excellent compatibility with a variety of polymers, including SIS, SBS and EVA. This means it can be easily incorporated into different adhesive formulations, providing manufacturers with versatility and flexibility. Whether you are formulating hot melt pressure-sensitive adhesives or general-purpose hot melt adhesives, the C5 Hydrogenated Hydrocarbon Resin-SHA158 Series can meet your needs.

The versatility of this resin extends beyond its use in hot melt adhesives. It can also be used as a tackifier for pressure-sensitive adhesives, further demonstrating its flexibility and utility in the adhesive industry. This makes it a valuable raw material for manufacturers looking to create high-performance adhesive products for a variety of applications.

Post time: Jan-16-2024