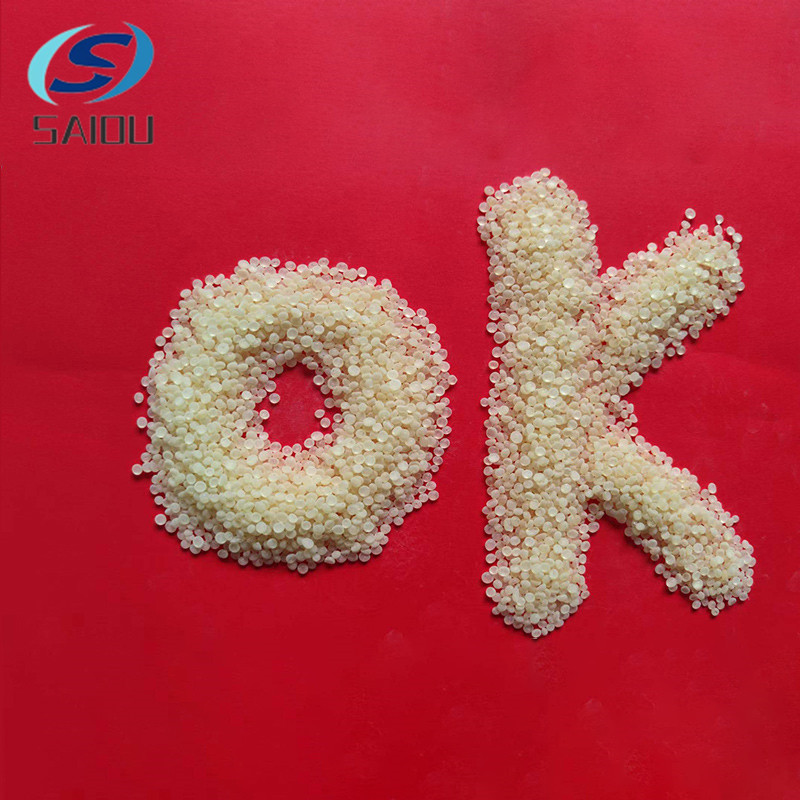

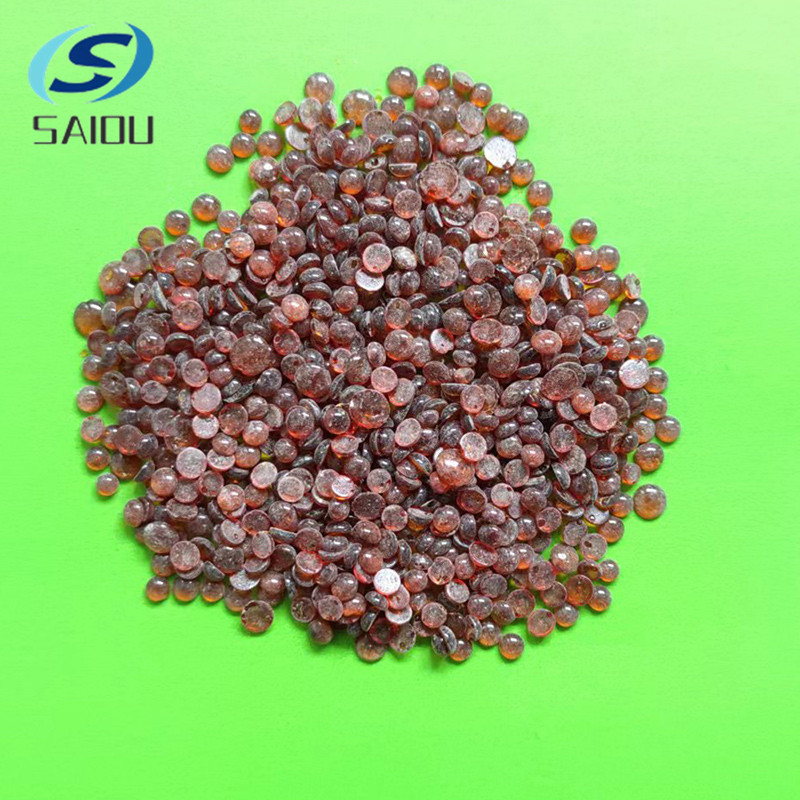

In the ever-evolving field of rubber manufacturing, the pursuit of high-performance materials is crucial. One such material that has received much attention is C9 hydrocarbon resin. Produced by industry leaders such as Tangshan Chemical Co., Ltd., this resin plays a vital role in improving the performance of rubber products.

C9 hydrocarbon resins are derived from the polymerization of C9 aromatics and are ideal additives for various rubber formulations. Their unique chemical structure gives them excellent compatibility with different types of rubber, including natural and synthetic rubbers. This compatibility is critical to improving the overall performance of rubber products, especially in terms of elasticity, strength and durability.

One of the most notable properties of C9 hydrocarbon resins is their ability to enhance the tack of rubber compounds. This property is particularly beneficial in applications such as adhesives and sealants where strong bonds are required. By incorporating C9 resins into rubber formulations, Tangshan Saiou Chemicals Co.Ltd., can achieve superior adhesion, ensuring that products will perform reliably in a variety of conditions.

Additionally, C9 hydrocarbon resins help improve the thermal stability of rubber products. This property is critical for high-temperature applications because it helps maintain the integrity and performance of the rubber over time. Tangshan Saiou Chemicals Co., Ltd. has invested in advanced production technology to ensure that its C9 resins meet the highest quality standards, providing customers with reliable rubber manufacturing solutions.

All in all, C9 hydrocarbon resins are set to revolutionize the rubber industry, offering improved performance and a wider range of uses. With the expertise of companies like Tangshan Saiou Chemicals Co.Ltd., can leverage this innovative material to produce high-quality rubber products that meet the demands of modern applications. As the industry continues to evolve, additives like these will become increasingly important, paving the way for more advanced and efficient rubber solutions.

Post time: Apr-28-2025